Teeccino Is Ready for Explosive Growth

Teeccino, a coffee alternative, has achieved product-market fit and is looking for explosive growth in the coming years.

ActivArmor’s 3D printed casts are far superior to traditional plaster casts. And its resilient CEO has a solid growth strategy.

I love companies that make me think, “Why didn’t I think of that?” These are almost never pure technology plays because the technology is already there. It’s merely waiting for a clever company with a clever idea to make profitable use of it.

The technology-in-waiting here is 3D printing (also known as “additive manufacturing”). ActivArmor is not making any extraordinary demands of 3D printing technology. It’s not asking it to make houses… artificial organs… or wagyu beef. It’s simply asking for hard plastic casts (the kind you use for broken bones or injuries).

But these hard plastic casts are better than traditional plaster casts in every way imaginable. They are…

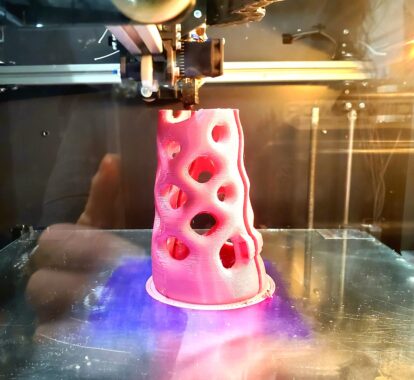

One of ActivArmor’s casts being 3D printed

That’s not all. Physicians can choose whether the cast should be loose or tightly fitted. Doctors can order them in locked or removable form. Even when locked, it’s easy for the doctor to remove them during the healing process for examination or at the end of the healing process.

Patients easily 3D-map their injured limb through ActivArmor’s app on an iPhone. Within three to four days, ActivArmor delivers the cast to them (or their doctor) for fitting. The cast is tailored to their exact fit. It’s super comfortable and versatile. Patients can shower or swim with them and easily put them on or remove them (if unlocked).

ActivArmor originally manufactured these casts in a central location and delivered them to clinics within three to four days of the request. In a move to make scaling easier while improving the customer experience, ActivArmor will be providing its 3D printing hardware and software directly to clinics. As soon as the first quarter of next year, patients at these clinics will have to wait mere minutes to receive their casts.

Data-driven startup investment ratings, AI analyst reports, and portfolio company exit and failure tracking

Advanced Search table full access, including ratings and analyst reports.

Charts and trends of capital raised by platform, security type, industry, and more.

Unlock Ratings and AI analyst report filters in the Advanced Company Search.

Track IPOs, acquisitions, failures and other exits for companies in your portfolio.

Teeccino, a coffee alternative, has achieved product-market fit and is looking for explosive growth in the coming years.

Zencastr, despite having just a few months of runway, has an impressive product that solves some major pain points for podcasters.

Remote golf coaching app Skillest is attracting a growing population of golfers with enthusiastic coaches and free advertising.

Sign up for our 3 minute newsletter with fresh takes on the top-rated investments and key startup trends you should know.

We care about the protection of your data. Read our Privacy Policy.